How to Use a Magnetic Ratchet Strap Winder for Effortless Securing

In today’s fast-paced world, the need for efficient and secure transportation has never been more critical. One tool that has shown remarkable effectiveness in this regard is the Magnetic Ratchet Strap Winder. This innovative device is designed to streamline the process of securing loads, making it not only easier but also safer. Whether you are a professional transport operator or an occasional user, mastering the use of the Magnetic Ratchet Strap Winder can significantly enhance your load management skills.

The Magnetic Ratchet Strap Winder offers a unique approach to handling ratchet straps, allowing users to wind and unwind straps with minimal effort. With its magnetic features, it simplifies the securing process, reducing the time and energy usually required to manage conventional straps. By incorporating this tool into your routine, you can ensure that your loads are tightly secured and ready for transport, all while minimizing strain and potential injury associated with manual strap management.

In this guide, we will explore the essential steps and techniques for utilizing the Magnetic Ratchet Strap Winder effectively. From setting it up correctly to tips on maximizing its potential, this comprehensive overview will provide you with the knowledge needed to make the most out of this valuable tool. Embrace the ease and efficiency that the Magnetic Ratchet Strap Winder brings to your securing tasks and experience a new level of convenience in load transportation.

Understanding the Basics of Magnetic Ratchet Strap Winders

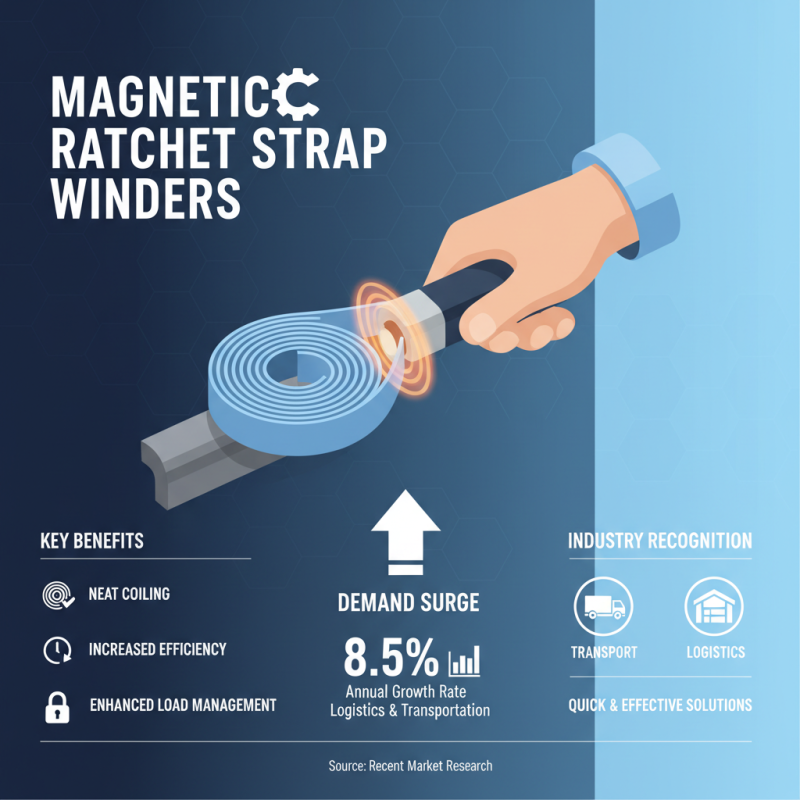

Magnetic ratchet strap winders are innovative tools designed to simplify the task of securing loads with ratchet straps. The primary function of these devices is to keep ratchet straps neatly coiled and easily retrievable for use, which greatly enhances efficiency in various industries. According to recent market research, the demand for such tools has increased significantly, with an estimated growth rate of 8.5% annually within the logistics and transportation sectors. This growing trend highlights the industry’s recognition of the importance of quick and effective load management solutions.

Understanding the basics of magnetic ratchet strap winders begins with their mechanism. These devices utilize strong magnets that allow users to attach them securely to a variety of metal surfaces, ensuring they remain in place during operation. This feature is particularly beneficial in environments where time-saving tools can lead to improved productivity. Studies indicate that improper strapping methods can lead to load failure, potentially causing accidents and delays; therefore, using a magnetic ratchet strap winder not only provides convenience but also enhances safety by minimizing the risk of improperly secured loads. The incorporation of such tools represents a shift towards more efficient operations in load transport and storage, reinforcing the industry's commitment to safety and effectiveness.

Benefits of Using a Magnetic Ratchet Strap Winder

Using a magnetic ratchet strap winder offers numerous benefits that enhance the efficiency and ease of securing cargo. The primary advantage is the effortless operation that these devices provide. By utilizing a magnetic mechanism, users can quickly and securely wind the straps without the hassle of tangled cords or manual tightening. This feature not only saves time but also minimizes physical strain, allowing users to focus on other important tasks.

Additionally, magnetic ratchet strap winders improve safety during the securing process. By ensuring that straps are tightly wound and perfectly aligned, these tools reduce the risk of load shifting during transport. Properly secured cargo minimizes the chances of accidents, protecting both the goods and the vehicle.

Furthermore, the compact design of many magnetic winders makes them easy to store and transport, providing convenience for both professionals and occasional users. Overall, the implementation of a magnetic ratchet strap winder leads to a more streamlined, safe, and efficient securing process.

Step-by-Step Guide to Operating a Magnetic Ratchet Strap Winder

Using a magnetic ratchet strap winder is a game-changer for anyone looking to secure items quickly and efficiently.

Begin by positioning the winder on a flat, stable surface. Ensure the strap is placed correctly into the winder's designated guide slot. This is crucial as it prevents tangling and ensures smooth operation.

Once the strap is secure, pull the loose end of the strap towards you. The magnetic feature will keep it in place as you set it up for tightening.

Next, turn the handle of the ratchet winder clockwise to tighten the strap around your load.

You should feel resistance as the strap tightens, which indicates it is gripping your items securely. Continue turning until the desired tension is achieved, but avoid overtightening to prevent damage to your cargo.

Once secured, press the release button, which disengages the ratchet mechanism and allows you to cut the excess strap if needed.

Finally, ensure that the magnetic base is firmly attached to your working surface to maintain stability during use. This step-by-step approach will make your securing tasks effortless and efficient.

Maintenance Tips for Prolonging the Life of Your Winder

Maintenance is crucial for ensuring the longevity and efficiency of a magnetic ratchet strap winder. Regular cleaning is one of the most important practices. According to the International Organization for Standardization (ISO), dust and debris can compromise the functionality of mechanical devices, leading to wear and tear. It is recommended to clean the winder after each use, using a soft cloth to remove dirt and moisture. For deeper cleaning, a mild detergent can be employed, ensuring all components are thoroughly dried before reassembly.

Additionally, lubrication plays a key role in maintenance. Studies from the American Society of Mechanical Engineers (ASME) indicate that properly lubricated moving parts can reduce friction and significantly extend the lifespan of tools and devices. A few drops of light machine oil on the moving parts of the winder can keep it operating smoothly and prevent rust. Furthermore, inspecting the strap for any signs of fraying or damage before use can prevent accidents and ensure optimal performance. Adopting these maintenance tips not only prolongs the life of your winder but also enhances safety and efficiency during securing tasks.

Common Mistakes to Avoid When Using a Magnetic Ratchet Strap Winder

When using a magnetic ratchet strap winder, there are several common mistakes that can lead to inefficiency or even unsafe securing practices. One significant mistake is failing to properly align the strap before winding it. Misalignment can cause the strap to bind or twist, making it difficult to release later. Always ensure that the strap is straight and free of knots before you begin winding. This simple step can save you time and frustration in the long run.

Another common error is over-tightening the strap during the winding process. While it may seem intuitive to secure the load as tightly as possible, over-tightening can lead to damage to your cargo or the strap itself. Instead, focus on achieving a snug fit that holds the load securely without applying excessive pressure. Additionally, regularly inspect the strap for any signs of wear or damage. Using a compromised strap can not only affect your load's security but can also pose safety risks during transport.

How to Use a Magnetic Ratchet Strap Winder for Effortless Securing - Common Mistakes to Avoid When Using a Magnetic Ratchet Strap Winder

| Mistake | Description | Solution |

|---|---|---|

| Improper Positioning | The winder is not aligned correctly, leading to ineffective winding. | Ensure the winder is positioned correctly at the start of the winding process. |

| Overloading the Strap | Exceeding the weight limit of the strap can lead to breakage. | Check the strap's weight capacity before use and distribute weight evenly. |

| Neglecting Maintenance | Not cleaning or lubricating the winder can cause it to malfunction. | Regularly clean and lubricate the winding mechanism to ensure smooth operation. |

| Ignoring Safety Precautions | Failing to wear protective gear while using the strap can lead to injuries. | Always use appropriate safety equipment such as gloves and goggles. |

| Wrong Strap Type | Using a strap not suited for your load can be dangerous. | Select the correct type of strap for your specific load requirements. |

Sitemap

polyester webbing sling, polyester round sling, 2inch ratchet tie down, ratchet tie down strap EN12195-2, 50MM 5T ratchet strap, eye webbing sling,

Latest News

Contact

-

Room709, Building 27, Shouchuang Airport International Center, No. 6 Changcheng South Road, Chengyang District, Qingdao, Shandong, China

-

7 Days a week from 10:00 am to 6:00 pm