What is an F Track Shoring Bar and Its Benefits in Construction?

In the dynamic field of construction, safety and efficiency are paramount. One innovative solution that has gained traction in recent years is the "F Track Shoring Bar." This essential tool provides critical support during the construction process, ensuring that structures maintain stability while work is being conducted. Renowned industry expert, Dr. Emily Carter, a structural engineer with over 20 years of experience, emphasizes the importance of this tool by stating, "The F Track Shoring Bar not only enhances safety, but it also streamlines the construction workflow, reducing downtime and project delays."

The F Track Shoring Bar plays a pivotal role in various construction applications, particularly in scenarios that require temporary support to facilitate building, renovation, or demolition activities. Its design allows for quick adjustments, accommodating the unique demands of different projects. As construction professionals continue to seek ways to improve project outcomes, understanding the benefits of the F Track Shoring Bar becomes increasingly relevant.

Ultimately, the integration of the F Track Shoring Bar in construction practices not only bolsters site safety but also contributes to the overall efficiency of building processes. As the industry evolves, the continued exploration of innovative shoring solutions will be crucial for meeting the challenges of modern construction.

What is an F Track Shoring Bar and Its Role in Construction Stability?

An F Track shoring bar is a structural element used in construction to enhance stability during various stages of a project. This innovative system allows for efficient vertical and horizontal bracing, crucial for maintaining the integrity of temporary structures, especially in deep excavation scenarios. According to the American Society of Civil Engineers, approximately 30% of construction-related accidents are linked to structural failures during the shoring process. The use of F Track shoring bars mitigates this risk by providing a robust framework that redistributes loads and enhances the overall stability of the site.

The role of the F Track shoring bar in construction cannot be overstated. It serves as a reliable support mechanism, ensuring that walls and other structures remain secure while materials are being installed or excavated. Research from the Construction Industry Institute indicates that implementing effective shoring systems can reduce project delays by up to 25%. This is particularly significant in urban areas where space is limited, and site safety is paramount. By utilizing an F Track shoring bar, contractors can assure greater compliance with safety regulations while optimizing workflow, leading to increased productivity and minimized financial risks associated with structural failures.

Benefits of F Track Shoring Bars in Construction

Key Advantages of F Track Shoring Bars in Structural Support Systems

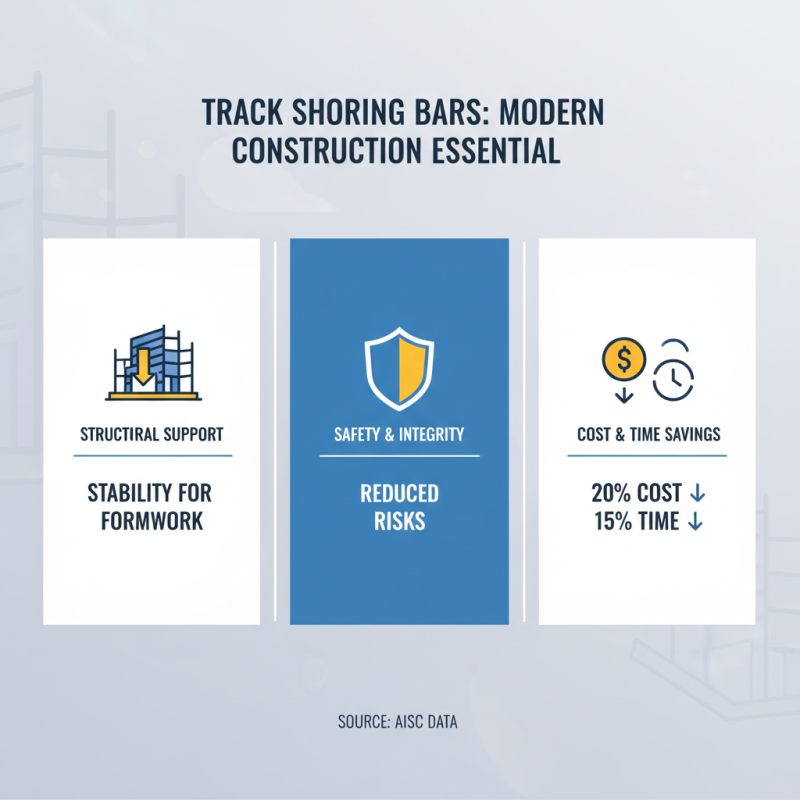

F Track shoring bars have become a critical component in modern construction projects, utilized primarily for their exceptional structural support capabilities. These bars, which are designed to provide stability for formwork systems, play an essential role in ensuring the safety and integrity of structures during the construction phase. The American Institute of Steel Construction (AISC) estimates that effective shoring systems can reduce construction costs by up to 20% while also decreasing project timelines by an average of 15%, making them a popular choice among contractors.

One of the key advantages of using F Track shoring bars is their versatility and adaptability. They can be easily adjusted to accommodate various load requirements and construction scenarios, facilitating efficient project management. According to a report by the Construction Industry Institute, employing innovative support systems like F Track shoring bars can enhance load distribution and minimize the risk of structural failures, leading to a safer work environment. Furthermore, their lightweight and robust design make them easier to handle onsite, which translates into lower labor costs and improved productivity.

By integrating F Track shoring bars into their structural support systems, construction professionals can achieve a superior balance between safety, efficiency, and cost-effectiveness. This adaptability not only supports a wide range of construction applications but also promotes sustainable practices by reducing material waste. As the construction industry continues to evolve, the adoption of advanced support technologies like shoring bars will remain instrumental in driving forward best practices and enhancing project outcomes.

Comparative Analysis of F Track Shoring Bars and Traditional Shoring Methods

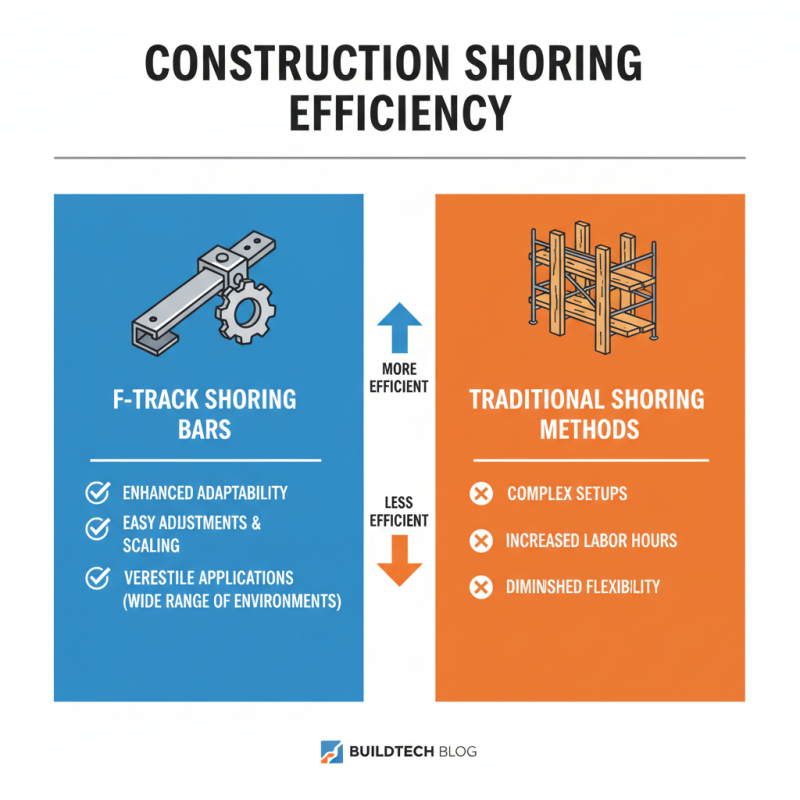

When examining the efficiency of construction techniques, the comparative analysis between F Track Shoring Bars and traditional shoring methods reveals significant distinctions in functionality and benefits. F Track Shoring Bars offer enhanced adaptability; their design allows for easy adjustments and scaling based on specific project requirements. In contrast, traditional shoring methods often require more complex setups, which can lead to increased labor hours and diminished flexibility on the job site. This adaptability means that F Track Shoring Bars can be utilized in various applications, making them suitable for a wider range of construction environments.

Another critical aspect is the structural integrity and safety provided by F Track Shoring Bars. When properly installed, they offer substantial support for vertical loads, ensuring stability in construction projects. Traditional methods, while effective, may rely on more cumbersome materials that can reduce overall site safety and increase risks during installation and dismantling. Additionally, F Track Shoring Bars tend to be lighter and easier to handle, resulting in less physical strain on workers, which ultimately enhances productivity. This comparative analysis highlights the growing preference for modern shoring solutions in contemporary construction practices.

Industry Data on Load Capacity and Efficiency of F Track Shoring Bars

When discussing the use of F Track shoring bars in construction, it’s crucial to focus on their load capacity and efficiency, as these factors significantly impact project success. Industry data shows that F Track shoring bars can support substantial weights, making them ideal for various applications, such as stabilizing walls and ceilings during renovations or new builds. Depending on the specifications and configurations, these bars can typically handle loads ranging from 3,000 to over 10,000 pounds, offering reliable solutions for both small and large construction projects.

Efficiency is another key aspect to consider. F Track shoring bars can be quickly installed and adjusted on-site, reducing the time needed for setup and allowing construction schedules to remain on track. This is particularly important in fast-paced environments where time is money. Moreover, their lightweight design facilitates easier handling and transportation, further contributing to overall project efficiency.

Tips: When selecting F Track shoring bars for your next project, always check the manufacturer’s load ratings and ensure they align with your specific needs. Regular inspections during use can also help maintain safety and performance, so consider integrating these checks into your project timelines. Lastly, consider the environmental conditions of your worksite, as weather and other factors may influence the performance of your shoring solutions.

Best Practices for Implementing F Track Shoring Bars in Construction Projects

Implementing F Track shoring bars in construction projects requires adherence to best practices to ensure effectiveness and safety. According to the Occupational Safety and Health Administration (OSHA), using shoring systems effectively can reduce the risk of structural failures and protect workers from accidents. A properly designed F Track system provides superior horizontal and vertical support for temporary structures or excavation sites. It is crucial to conduct a comprehensive site assessment and load calculation before installation, ensuring the system is tailored to the specific needs of the project and the ground conditions present.

Training workers on the correct use of F Track shoring systems is another vital best practice. A report from the National Institute of Occupational Safety and Health (NIOSH) indicates that over 50% of construction-related incidents stem from improper use of equipment. By providing thorough training sessions that incorporate the latest safety protocols, workers can better understand the potential hazards and the correct operational procedures. Additionally, regular inspections and maintenance of the shoring bars during the project can enhance safety and durability, ensuring that any wear or damage is addressed promptly. Engaging in these best practices not only aligns with regulatory standards but also promotes a safer work environment, which is essential for the successful completion of construction projects.

What is an F Track Shoring Bar and Its Benefits in Construction? - Best Practices for Implementing F Track Shoring Bars in Construction Projects

| Dimension | Description | Benefits | Best Practices |

|---|---|---|---|

| Material | High-strength steel | Durability and longevity | Select appropriate material grades |

| Load Capacity | Varies from 5000 to 30000 lbs | Supports heavy construction loads | Assess load requirements accurately |

| Adjustability | Height and width can be adjusted | Flexible use in various applications | Ensure proper adjustment before use |

| Installation Time | Quick installation | Reduces project timelines | Follow manufacturer guidelines |

| Safety Features | Integrated safety features | Enhanced worker safety | Regular safety training and updates |

Sitemap

polyester webbing sling, polyester round sling, 2inch ratchet tie down, ratchet tie down strap EN12195-2, 50MM 5T ratchet strap, eye webbing sling,

Latest News

Contact

-

Room709, Building 27, Shouchuang Airport International Center, No. 6 Changcheng South Road, Chengyang District, Qingdao, Shandong, China

-

7 Days a week from 10:00 am to 6:00 pm