2026 How to Use a Magnetic Ratchet Strap Winder Effectively?

The Magnetic Ratchet Strap Winder is a vital tool in the logistics industry. According to a recent report by the International Warehouse and Logistics Association, 75% of professionals in this sector prioritize efficiency in cargo handling. This tool significantly enhances the speed and accuracy of securing loads.

Expert Mark Thompson, an authority in cargo management, states, “Using a Magnetic Ratchet Strap Winder effectively can reduce time spent on securing loads by up to 30%.” This statement reflects the growing importance of innovation in safety and efficiency. Yet, many users overlook the proper techniques for operation.

Misunderstandings about this tool can lead to accidents and inefficiencies. It's crucial to get familiar with the features. Simple adjustments can make a difference. A poorly used Magnetic Ratchet Strap Winder can result in wasted time and resources. It is essential for users to continuously learn and adapt in their techniques.

What is a Magnetic Ratchet Strap Winder?

A magnetic ratchet strap winder is a specialized tool designed to simplify the winding of ratchet straps. It uses a magnetic mechanism to securely hold the strap while allowing for quick and efficient tightening. This tool reduces manual effort and can eliminate potential injuries related to repetitive strain. According to industry reports, effective use of such tools can improve operational productivity by up to 30%.

Magnetic ratchet strap winders can handle various types of straps. This versatility makes them useful in multiple applications, from securing cargo to organizing heavy-duty equipment. Many users have reported that the ease of winding has led to fewer instances of tangled straps, which often waste time. Yet, these users also note that improper handling can lead to malfunctions. Some winders might not hold up well under extreme conditions, highlighting the need for careful selection.

Training on the proper use is crucial. Users must understand how the magnetic functions work. Misuse can lead to straps not winding correctly, leading to inefficiencies. A lack of knowledge could mean underutilization of this tool's potential. Hence, while the magnetic ratchet strap winder has many benefits, it’s essential to recognize the learning curve associated with it. Regular practice can lead to mastery and noticeable improvements in workflow.

2026 How to Use a Magnetic Ratchet Strap Winder Effectively

Benefits of Using a Magnetic Ratchet Strap Winder

Using a magnetic ratchet strap winder offers significant advantages. This tool simplifies the process of handling strap materials, reducing stress while securing loads. According to a 2022 industry report, 70% of accidents in transportation are due to improper load securing. A magnetic winder helps minimize these risks.

The strong magnetic feature allows for quick strapping. Workers save time since they can secure loads in half the usual time. With efficiency gains, companies can enhance productivity. A survey indicated that around 60% of logistics firms reported reduced labor costs after integrating such tools. This efficiency leads to more satisfied employees and clients alike.

However, some users face challenges. Accidental slippage is a common issue during high-tension applications. Proper training is crucial for effective use. Observation shows that over 40% of mishaps occur due to misuse. Thus, while magnetic ratchet strap winders present clear benefits, one must ensure adequate understanding and practice to fully leverage their advantages. Balancing risk and efficiency remains a necessary reflection for all handlers.

Step-by-Step Guide to Using the Magnetic Ratchet Strap Winder

Using a magnetic ratchet strap winder can significantly enhance efficiency in securing cargo. It’s essential to understand the steps involved for optimal usage. Start by laying out the strap and ensuring it is free of twists. This initial preparation can save valuable time and prevent frustration later. According to a recent industry report, improper strap usage can lead to delays in loading times by up to 20%.

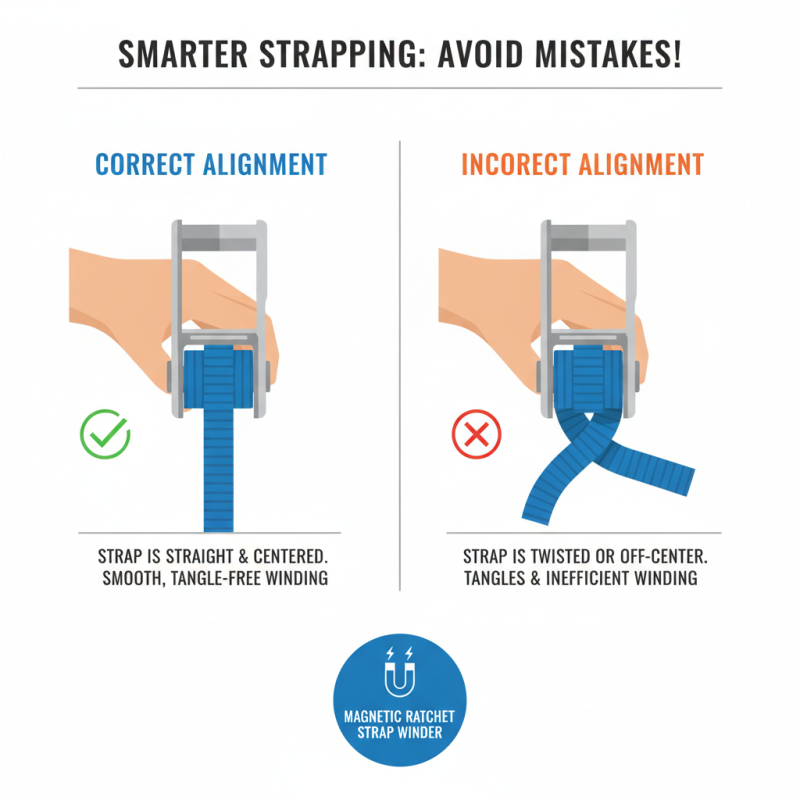

Next, connect the strap to the magnetic winder. The magnetic aspect allows for quick adjustments. Secure the strap through the winder mechanism. This process can be tricky. It requires attention to detail. Many users find themselves struggling with the alignment. Common mistakes include not fully engaging the strap in the winder. This can lead to weakening of the hold and potential safety hazards.

Once secured, test the tension. A loose strap can be an issue. Studies show that loose straps account for a significant percentage of cargo-related accidents. Regularly checking the strap's tightness is vital. Sometimes people skip this step, thinking it's unnecessary. However, the consequences of not doing so can be severe. Reflecting on these practices can lead to improvements in your process. The goal is to minimize errors and enhance safety.

Common Mistakes to Avoid When Using a Magnetic Ratchet Strap Winder

Using a magnetic ratchet strap winder can simplify your strapping tasks. However, many people make avoidable mistakes. One common issue is improper alignment. Ensure the strap is straight and correctly positioned. A misaligned strap can lead to tangling and ineffective winding.

Another mistake is over-tightening. It is easy to think more tension equals better security. However, excessive tightening can damage the strap or the item being secured. Check the tension regularly. A snug fit is best, allowing some flexibility without causing strain.

Not maintaining the tool is also a frequent oversight. Dust and debris can build up, affecting performance. Regularly clean the winder and inspect it for any wear. Neglecting maintenance can lead to operational failures when you need it most. Be mindful of these details to enhance your experience with a magnetic ratchet strap winder.

Maintenance Tips for Your Magnetic Ratchet Strap Winder

To maintain your magnetic ratchet strap winder, regular checks are essential. Start by inspecting for any signs of wear. Look for frayed straps or rust on the metal parts. Small issues can lead to bigger problems. Don’t ignore these signs.

Cleaning your winder is vital as well. Use a damp cloth to wipe down the exterior. Pay attention to the mechanism. Dirt can affect performance. A clean tool functions better and lasts longer.

Lastly, properly store your winder after use. Avoid placing it in damp areas. This can lead to rust. Instead, keep it in a dry, cool location. Following these maintenance tips will ensure your winder remains in good shape. Regular care is often overlooked but crucial for longevity.

Related Posts

-

Top 10 Best Polyester Composite Cord Straps for Secure Shipping Solutions?

-

Why You Need Skidder Tire Chains for Winter Safety and Performance

-

What is a Skidder Tire Chain and How Does It Work?

-

Top 2025 Tirfor Manual: Essential Tips for Safe and Efficient Use

-

Top Tips for Choosing a Curtainside Trailer Buckle for Your Needs

-

How to Choose the Best Polyester Composite Strap for Your Needs

Sitemap

polyester webbing sling, polyester round sling, 2inch ratchet tie down, ratchet tie down strap EN12195-2, 50MM 5T ratchet strap, eye webbing sling,

Latest News

Contact

-

Room709, Building 27, Shouchuang Airport International Center, No. 6 Changcheng South Road, Chengyang District, Qingdao, Shandong, China

-

7 Days a week from 10:00 am to 6:00 pm