How to Choose the Best Polyester Composite Strap for Your Needs

In the realm of packaging solutions, the choice of strapping materials can significantly impact efficiency and security in logistics. Among various options, Polyester Composite Strap has emerged as a leading choice for many businesses due to its strength, durability, and versatility. According to a recent industry report by Smith & Associates, polyester strapping accounts for over 30% of the overall strapping market, highlighting its growing preference among suppliers and manufacturers. This surge in adoption is attributed to its remarkable ability to withstand varying environmental conditions while providing optimal load stability.

Expert in the field, Dr. Emily Johnson, a renowned packaging technologist, stated, "Choosing the right strapping material is essential for maximizing cargo safety and reducing operational costs." Her insights reflect the general consensus among industry leaders that Polyester Composite Strap combines performance with cost-effectiveness, making it an ideal choice for businesses looking to enhance their packing processes. In this guide, we will explore the critical factors to consider when selecting the best Polyester Composite Strap for your needs, ensuring you can effectively balance durability, cost, and application requirements in your strapping solutions.

Understanding the Basics of Polyester Composite Straps

Polyester composite straps are a critical tool in various industries, primarily used for securing, bundling, and transporting goods. Understanding the basics of these straps is essential to selecting the right one for your needs. At their core, polyester composite straps are crafted from a blend of polyester and other materials, offering a balance of strength, durability, and flexibility. This combination makes them an ideal choice for applications where high tensile strength is required, such as in heavy-duty shipping and packaging.

One of the primary advantages of polyester composite straps is their resistance to environmental factors. Unlike steel straps, which can be susceptible to rust and corrosion, polyester composite straps maintain their integrity in a variety of conditions, making them suitable for both indoor and outdoor use. Additionally, they do not stretch excessively under load, ensuring that your cargo remains secure during transport. It's also important to consider the width and thickness of the strap, as these characteristics will affect its load-bearing capacity and ease of use. By understanding these fundamental properties, you can make an informed choice that meets your specific requirements.

Identifying Your Specific Application Needs

When selecting a polyester composite strap, it’s crucial to first identify your specific application needs. The intended use of the strap can significantly influence the type of material, strength, and features you require. For instance, if the strap is meant for heavy-duty applications, such as securing large cargo during transportation, you’ll need a composite strap that offers high tensile strength and resistance to wear and tear. Assess the environmental conditions the strap will face, such as exposure to UV rays or chemicals, to ensure it can withstand these factors without degradation.

In addition to strength and durability, consider the dimensions and weight capacity of the strap. The width and thickness of the polyester composite strap will affect its performance under load, so be sure to match these specifications with your application requirements. Furthermore, evaluate the method of securing the strap. Depending on whether you’ll be using a buckling mechanism, seals, or other fastening methods, selecting a compatible strap is essential for achieving optimal safety and efficiency in your operations. By thoroughly analyzing these aspects, you'll be better equipped to choose the most suitable polyester composite strap for your needs.

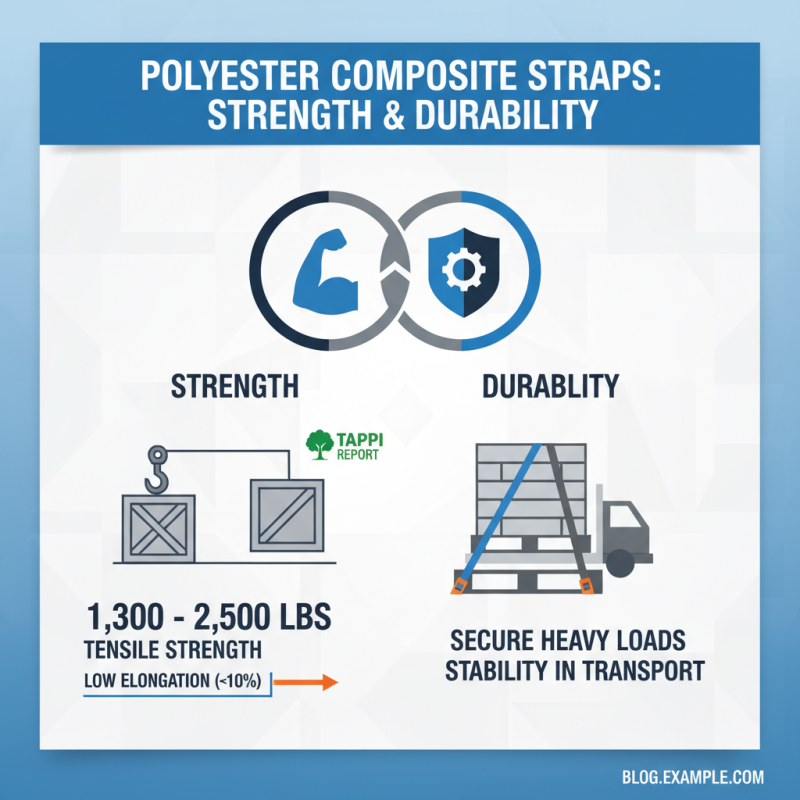

Evaluating Strength and Durability Requirements

When selecting a polyester composite strap, evaluating strength and durability is paramount. Polyester straps are favored for their impressive tensile strength, often ranging between 1,300 to 2,500 pounds, depending on the width and thickness of the strap. According to a report by the Technical Association of the Pulp & Paper Industry (TAPPI), polyester straps exhibit a low elongation percentage, typically under 10%. This characteristic ensures that the strap will not stretch excessively under load, providing stability during transport and securing heavy loads effectively.

In terms of durability, polyester straps are resistant to moisture, UV light, and weathering, making them ideal for both indoor and outdoor applications. Research from the International Journal of Advanced Manufacturing Technology highlights that polyester composite materials can significantly outlast polypropylene counterparts in harsh environments, boasting a lifespan increase of up to 30% in exposure tests. Additionally, their resistance to chemical damages, especially from oils and solvents, amplifies their long-term usability in various industries, including packaging and logistics. Understanding these strengths can help you choose the right polyester composite strap that meets your specific operational needs while ensuring the safety and integrity of the secured loads.

Comparing Different Types of Polyester Composites

When selecting the best polyester composite strap for your needs, it's crucial to understand the various types of polyester composites available in the market. These composites generally differ in their tensile strength, flexibility, and resistance to environmental factors. For instance, studies show that high-tensile polyester composite straps can withstand significant loads, with some options offering break strengths exceeding 10,000 pounds. According to industry reports, the tensile strength of these straps typically ranges from 4,000 to 12,000 pounds, which is essential for heavy-duty applications such as shipping and logistics.

In addition to strength, the flexibility of polyester composites plays a critical role in their application. Many versions are designed to be more pliable, allowing for easier handling and secure bundling of products. Recent findings from the Packaging Association highlight that flexible polyester composites reduce the risk of damage during transport, particularly for delicate or irregularly shaped items. Environmental resistance is another factor; many modern polyester composites are engineered to resist UV rays and moisture, ensuring durability in various conditions. Overall, understanding these differences can help you make a more informed choice tailored to your specific logistical or packaging needs.

Selecting the Right Size and Specifications for Your Project

When selecting the right size and specifications for your polyester composite strap, it's essential to consider the specific requirements of your project. Start by assessing the load capacity needed for your application.

Polyester composite straps come in various widths and thicknesses, which directly influence their strength and durability. For heavy loads, opt for thicker straps with a higher tensile strength, ensuring they can handle the stress without risk of breaking. Always refer to the manufacturer's guidelines regarding load limits to avoid potential failures during use.

The length of the strap is another crucial factor. Measure the dimensions of the items you intend to secure and account for any additional length needed for tying knots or securing to anchor points. Ensure that you choose a strap that provides enough length without excess, as that can lead to inefficient handling or increased bulk.

Furthermore, consider environmental factors such as exposure to UV light or chemicals, which may affect the strap's longevity. Opt for straps formulated to withstand your specific environmental conditions to ensure reliability and safety throughout your project.

Related Posts

-

Why Choosing the Right Flatbed Trailer Supplies is Essential for Your Business

-

Top 2025 Tirfor Manual: Essential Tips for Safe and Efficient Use

-

What is an F Track Shoring Bar and Its Benefits in Construction?

-

Why You Need Skidder Tire Chains for Winter Safety and Performance

-

2025 How to Choose the Best Curtainsider Cargo Straps for Secure Transport

-

How to Use a Magnetic Ratchet Strap Winder for Effortless Securing

Sitemap

polyester webbing sling, polyester round sling, 2inch ratchet tie down, ratchet tie down strap EN12195-2, 50MM 5T ratchet strap, eye webbing sling,

Latest News

Contact

-

Room709, Building 27, Shouchuang Airport International Center, No. 6 Changcheng South Road, Chengyang District, Qingdao, Shandong, China

-

7 Days a week from 10:00 am to 6:00 pm