Top 10 Best Polyester Composite Cord Straps for Secure Shipping Solutions?

In recent years, the demand for efficient shipping solutions has surged. The global e-commerce market is projected to reach $4.9 trillion by 2021, which emphasizes the need for reliable packaging. Amid this growth, the importance of using quality materials cannot be overlooked. Polyester Composite Cord Strap has emerged as a preferred choice among shipping companies.

Studies indicate that polyester straps outperform traditional steel straps in terms of strength and flexibility. They can withstand extreme weather conditions and heavy loads. Furthermore, these straps are lightweight, making them cost-effective for shipping purposes. However, it's essential to recognize that not all polyester composite cord straps are created equal. Factors like thickness, tensile strength, and manufacturing quality play significant roles in performance and durability.

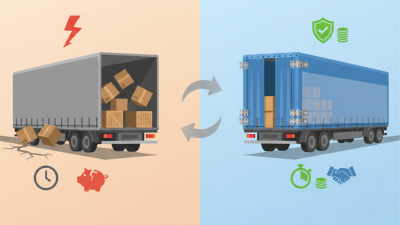

While some use cheaper alternatives, this could lead to compromised safety and security during transport. Real-world examples highlight incidents where inferior-quality straps led to cargo damage. Companies must reflect on their choices to ensure that the straps they use meet industry standards. Investing in top-grade Polyester Composite Cord Strap can enhance the safety of shipments and protect valuable goods.

Understanding Polyester Composite Cord Straps and Their Benefits

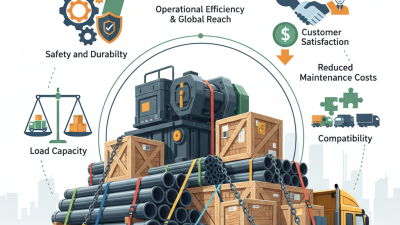

Polyester composite cord straps are essential for secure shipping. They offer strength and flexibility for various applications. These straps are lightweight yet durable, making them suitable for heavy-duty shipping needs. Their resistance to moisture and UV rays ensures longevity, even in harsh environments. This feature is crucial when shipping items internationally.

Using polyester cord straps can enhance efficiency in packaging. They are easy to use and can withstand significant tension without breaking. However, improper use can lead to failures. Ensuring proper tightness is important to avoid shifting loads during transport. Straps should be checked for wear and tear before reuse. A worn strap may seem fine but can fail unexpectedly, resulting in lost items.

The benefits of polyester cord straps extend beyond strength. They are often more environmentally friendly compared to traditional metal straps. Their lightweight nature reduces shipping costs. Yet, it’s essential to remain vigilant about their limitations. Overloading can compromise their effectiveness. Regular inspection should not be overlooked to maintain shipping integrity.

Key Features to Look for in Polyester Composite Cord Straps

When selecting polyester composite cord straps, several key features are essential. First, check the tensile strength of the straps. This strength determines how much weight they can securely hold during shipping. Look for straps rated for heavy-duty use. They should withstand tension without breaking or fraying.

Next, consider the width and thickness of the straps. Wider straps distribute weight more evenly. This feature reduces the risk of damage to shipped items. Additionally, flexible straps can adapt to different shapes and sizes of packages. Look for options that balance flexibility and durability.

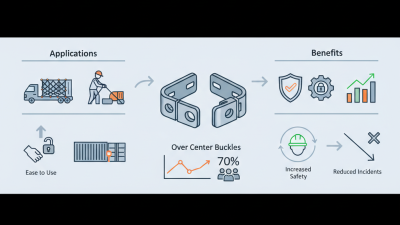

Finally, examine the type of closure used for the straps. Quality buckles should be easy to use yet secure. Poorly designed closures may lead to accidental loosening during transit. Inspecting the straps for any signs of wear or defects before use can save you from potential losses. Pay attention to these details; they can make a significant difference in shipping efficiency and safety.

Top 10 Best Polyester Composite Cord Straps for Secure Shipping Solutions

| Cord Strap Type | Load Capacity (lbs) | Width (inches) | Length (feet) | Key Feature |

|---|---|---|---|---|

| Standard Polyester Strap | 1,500 | 1 | 50 | UV Resistant |

| Heavy Duty Composite Strap | 2,000 | 1.5 | 40 | High Tensile Strength |

| Lightweight Cord Strap | 1,000 | 0.75 | 60 | Easy to Handle |

| Composite Cargo Strap | 2,500 | 1.25 | 50 | Heat Resistant |

| Reinforced Polyester Strap | 3,000 | 1.5 | 35 | Abrasion Resistant |

| Eco-Friendly Strap | 1,200 | 1 | 60 | Made from Recycled Materials |

| Weatherproof Cord Strap | 1,800 | 1.5 | 50 | Water Resistant Coating |

| High Visibility Strap | 2,200 | 1 | 40 | Fluorescent Color |

| Multi-Use Composite Strap | 2,700 | 1.25 | 50 | Versatile Application |

| Durable Strap with Hooks | 3,200 | 1 | 55 | Includes Metal Hooks |

Top 10 Best Polyester Composite Cord Straps for Secure Shipping

When shipping goods, choosing the right equipment is crucial. Polyester composite cord straps stand out for their strength and versatility. They effectively secure various items during transit. These straps come in different widths and lengths, accommodating many shipping needs.

Many users appreciate the lightweight nature of these straps. It helps in reducing overall shipment costs. However, some straps may not meet high tension requirements. It's essential to evaluate your shipment’s specific needs before selecting a strap. Look for features like weather resistance and UV protection to ensure durability.

Despite their benefits, polyester straps can be tricky to use. Improper tension may lead to package damage. Additionally, some users report difficulty in handling. A learning curve exists in mastering the best application techniques. Taking the time to understand these straps can significantly improve the security of your shipments.

Comparing the Durability and Strength of Leading Cord Strap Brands

When shipping goods, the choice of cord straps is crucial. Polyester composite cord straps are a popular option for their durability and strength. These straps can handle heavy loads and resist wear and tear from the environment. However, not all cord straps perform equally. Some may stretch, while others can fray unexpectedly. It’s essential to examine the materials used. Look for straps with high tensile strength ratings and resistance to UV degradation.

Testing the strap under real conditions is vital. A robust strap should withstand temperature fluctuations and moisture without losing integrity. Be mindful of how different brands perform in various scenarios. While one strap may excel in dry conditions, it might falter in humid environments. Evaluating your shipping environment helps in selecting the right cord strap.

Some users report that their chosen straps have failed under stress. This highlights the importance of not relying solely on specifications. Real-world testing can uncover weaknesses. Trusting reviews from multiple sources can provide better insights into performance. Always remember that even top-rated straps might have limitations. Staying informed can lead to better shipping solutions.

Tips for Properly Using Polyester Composite Cord Straps in Shipping

Polyester composite cord straps are revolutionizing shipping security. These straps can withstand significant weight and provide excellent shock absorption. Industry data shows that using high-quality straps can reduce shipment damage rates by up to 30%. However, their effectiveness greatly depends on proper usage.

When utilizing these straps, ensure they are sized appropriately for the load. Straps that are too short may not secure items properly. Conversely, those that are too long could lead to entanglements or ineffective tension. Always keep a tensioning tool nearby, as proper tension ensures durability. Professionals recommend maintaining a tension of around 600 pounds for average shipping loads.

Users often overlook the importance of inspecting straps before each use. Even minor wear can lead to failure. Reports indicate that 15% of shipping incidents occur due to equipment failure. This emphasizes the need for consistent maintenance checks. Make it a routine to discard any frayed or damaged straps. Taking these steps can significantly bolster overall shipping safety.

Related Posts

-

How to Choose the Best Polyester Composite Strap for Your Needs

-

Top Benefits of Using Polyester Composite Cord Strap for Your Packaging Needs?

-

Why Are Curtainsider Buckles Essential for Freight Transport?

-

Why Choosing the Right Flatbed Trailer Supplies is Essential for Your Business

-

What is a Skidder Tire Chain and How Does It Work?

-

Understanding Over Center Buckle Applications and Benefits

Sitemap

polyester webbing sling, polyester round sling, 2inch ratchet tie down, ratchet tie down strap EN12195-2, 50MM 5T ratchet strap, eye webbing sling,

Latest News

Contact

-

Room709, Building 27, Shouchuang Airport International Center, No. 6 Changcheng South Road, Chengyang District, Qingdao, Shandong, China

-

7 Days a week from 10:00 am to 6:00 pm